Featured Metro Restyling Video

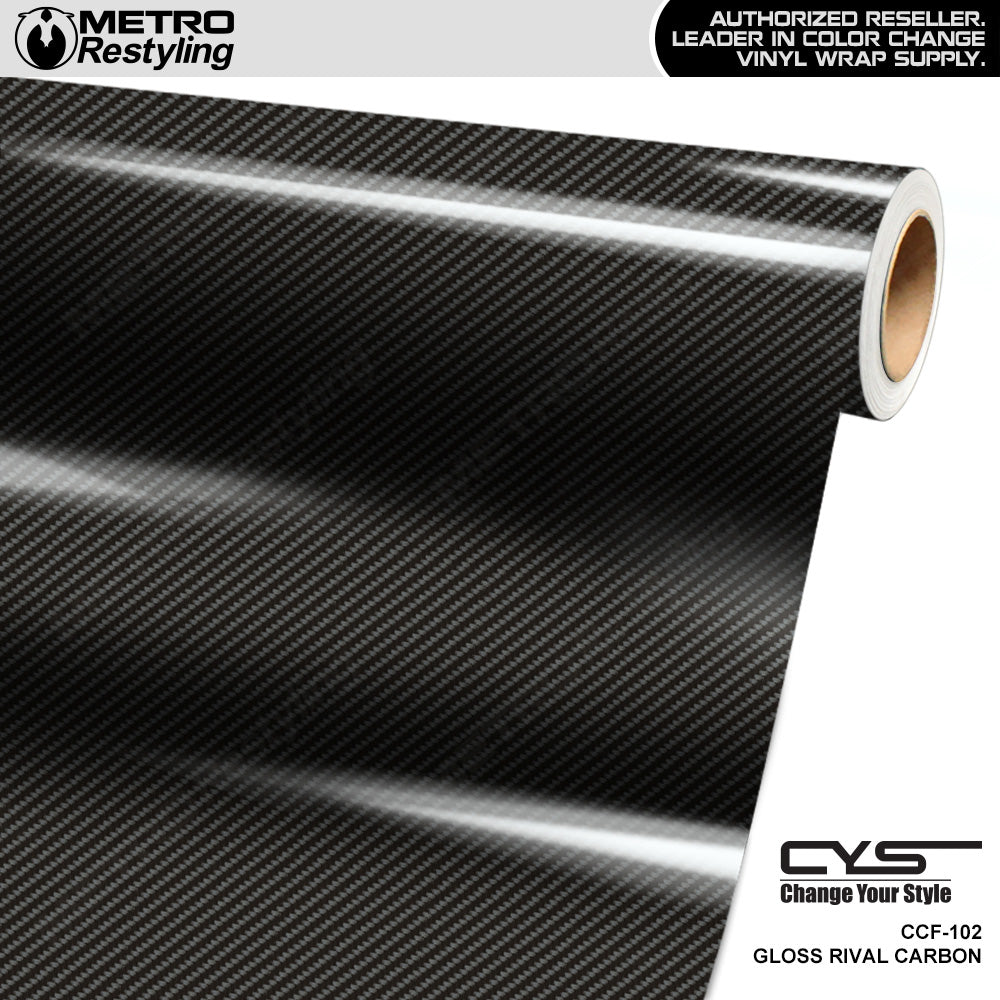

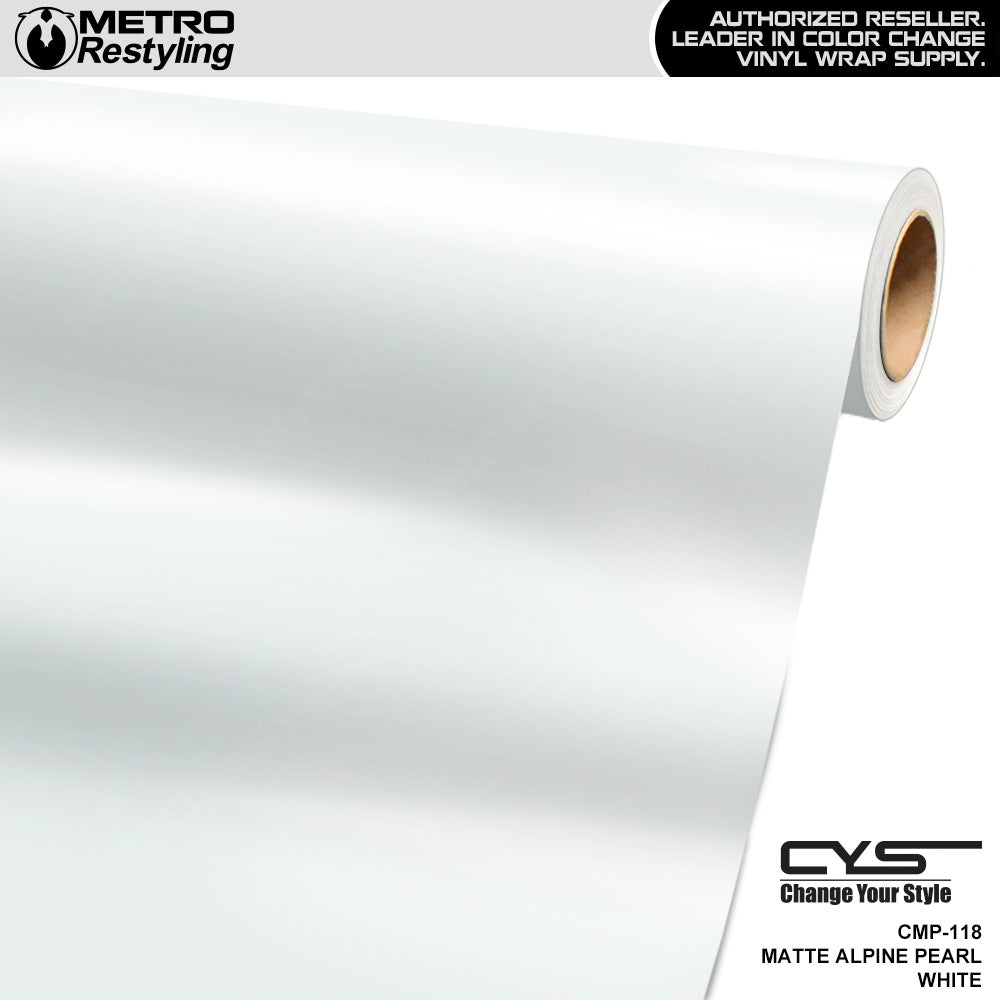

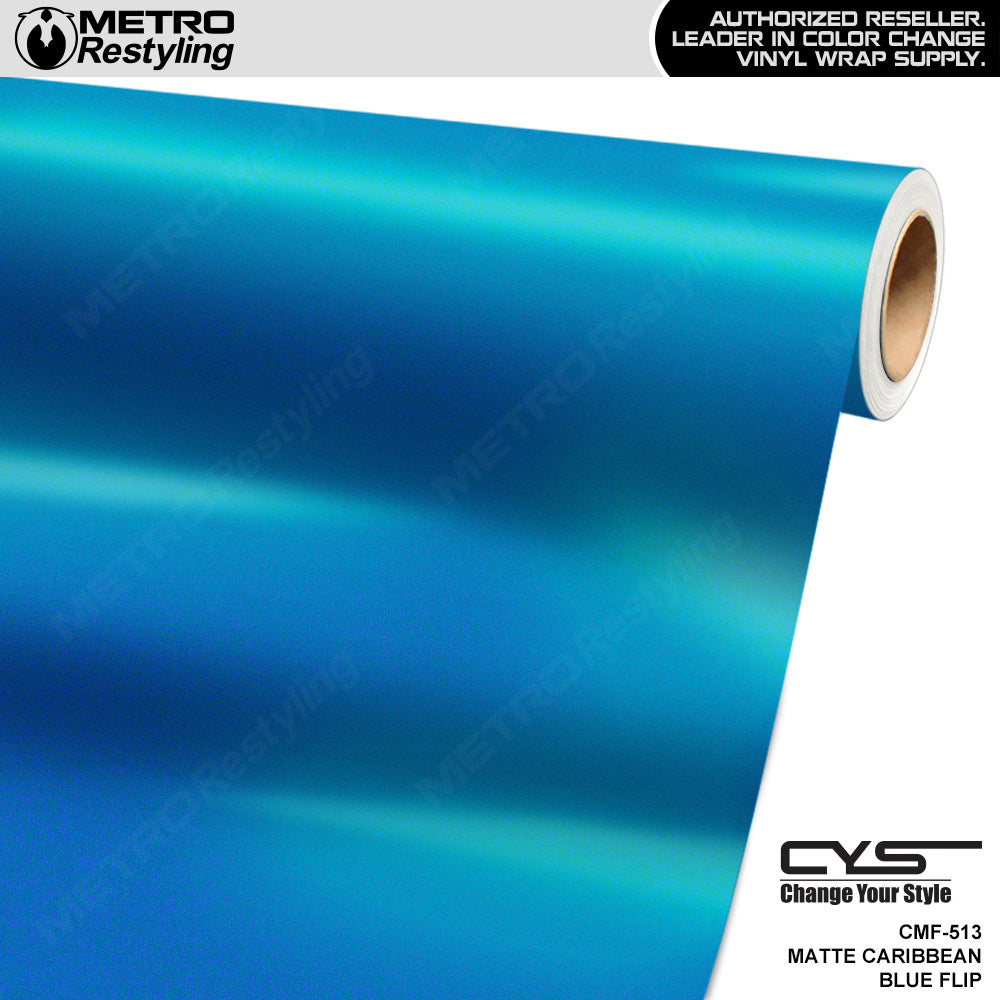

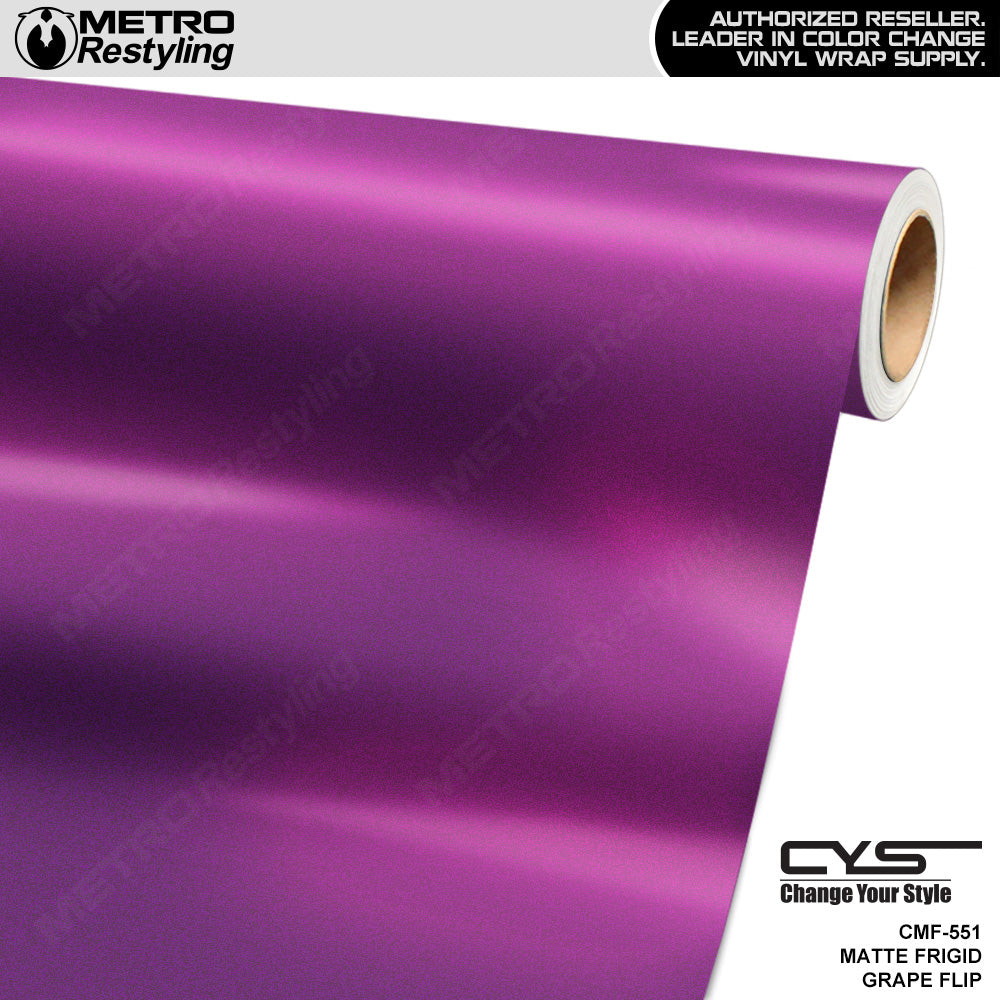

Car Wrap Colors

View all

Top Sellers

Car Wrap Prints

View all

Spotlight of the Week

Wrapped by: @illnositywraps

Cybertruck Wrapped in Avery Dennison Satin Frozen Ocean Vinyl Wrap

Submit photos of your own completed wrap projects for a chance to get featured!

Get FeaturedBlog posts

View all

Crazy Car Wrap Ideas

Mustang Wraps: Customer Showcase

Frequently Asked Questions

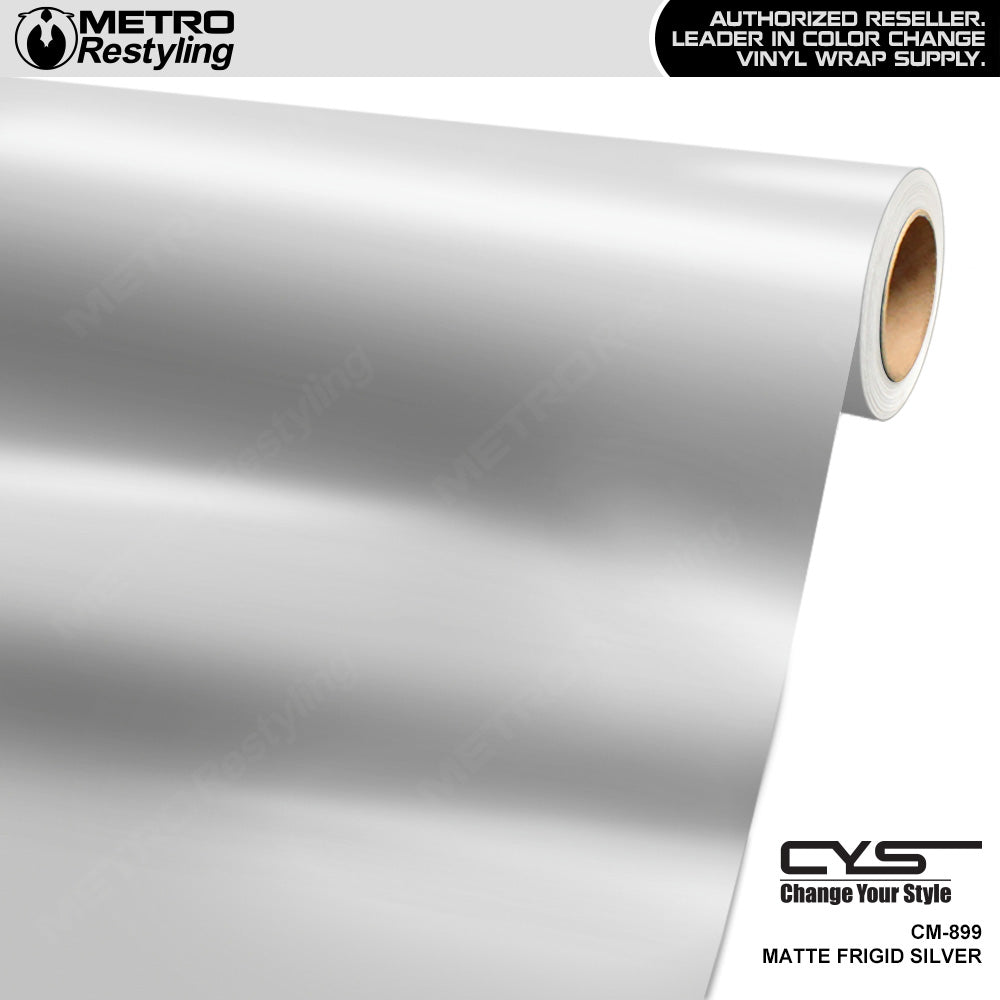

Car Vinyl Wraps are a popular way to customize the style and color of your car. Car wraps are made from a thin, flexible vinyl film applied to the car's surface. We offer many premium cast vinyl wraps from experienced major brands like 3M, Avery, KPMF, Hexis, Orafol, and Metro Wrap.

Car wraps are available in various colors and finishes, like gloss, matte, satin, iridescent, chrome, and more. Vinyl Wrap can be used on any vehicle surface, removed without damaging the paint, and reapplied if necessary. Car wraps are an easy and affordable way to personalize your car and make it stand out from the rest.

Some basic guidelines to use when choosing the amount of material you need to wrap a vehicle:

- 60 inches by 45 feet for compact cars (Volkswagen GTI, Honda Civic, Mazda3)

- 60 inches by 60 feet for standard cars (Toyota Camry, Honda Accord, Hyundai Sonata)

- 60 inches by 75 feet for trucks (Ford F-150, Ram 1500, Chevy Silverado)

Please keep in mind that the amount of material you need depends on your skill level. If you are a beginner to intermediate level wrapper, we recommend ordering more to cover for any potential mistakes made in the wrapping process.

On average, well-installed car wraps will last for 3-5 years, but some wraps can remain in excellent shape for 7 years or longer.

Some factors that determine how long your vinyl wrap lasts include:

- Type of material used; major brands last longer. (VVivid, VinylFrog, Teckwrap, and other China-made films are not major brands)

- Contaminates; chemicals, tree sap, water spots, and not cleaning your wrap.

- Where you live; hot climates with a lot of sun and states that use salt for managing snow can decrease the lifespan

The cost of vinyl wrapping a vehicle depends on a few factors that need to be taken into account, including:

- The type of material; every brand has different pricing options, sometimes for the same material.

- The amount of material; the more material you need, the more expensive your purchase will be.

- DIY or hiring an installer; if you are wrapping a vehicle yourself, you won't need to take into account paying someone else to get the project done.

Please keep in mind that hiring a professional vinyl wrap installer will typically run you anywhere between $1,500 - $3,000. These prices do not reflect all installers, it is only an estimation.

Please visit our FAQ page for additional information regarding orders, delivery, pricing, and more.

We got you covered

At Metro Restyling, we’re committed to offering you the best products on the market at discount prices. Explore our products, learn about our reputation, and find out how to connect with our company. See what sets us apart and enables us to offer you a wide range of name-brand products at affordable prices.